Resists & Coatings

Resists & Coatings

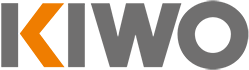

A resist can partially mask a surface with a certain design or completely cover the surface before finishing, further processing or transporting the material, i.e. it protects the surface against external influence. Applications such as etching, sand blasting, sputtering and selective brushing of metal surfaces are the main focus of the sales programme.

A new and technically interesting field, opening up many possibilities.

Application method

UV curing resist for selective brushing of metal surfaces, e.g., for the production of vehicle interior parts, exclusive cosmetic packaging or industrial signage. Normally, KIWOMASK UV 7322 VP is applied as a 2-component product. By adding 5% KIWOMIX ZL 1073 and after UV crosslinking, the result is a special, paint-like surface with excellent glide properties and very good mechanical resistance during the brushing process. Excellent printing properties and optimal thixotropy enable sharp-edged printing of the finest structures. Cross-linking with UV light enables very short process cycles without drying time. Aside from the common stripping methods with slightly alkaline stripping products, the resist can be removed with water at room temperature.

UV curing resist for selective etching of metal surfaces, e.g. for the production of vehicle interior parts or industry signs. KIWOMASK UV 871 is resistant against acidic etching processes (e.g. ferric(III) chlorid). Excellent printing properties facilitate a sharp-edged print of finest structures. Cross linking by UV light provide short processing cycles without drying time. Aside from the common stripping methods with slightly alkaline stripping products, KIWOMASK UV 871 can be removed with hot water (60 ° – 80 ° C / 140 ° – 175 ° F).

Screen-printable, thermal drying etch and sputter resist for glass and metal surfaces. Suitable for vacuum coating processes at higher temperatures (e.g., PVD or magnetron sputter coating) and etching processes with acidic etching solutions commonly used in practice. Good resistance to aqueous cleaning processes. Strip with caustic soda, soda or potassium hydroxide (3 – 5%), or with mild, organic solvents (for example KIWOCLEAN LM 606).

Inkjet resist for decorative or functional sputter and PVD coating of technical glass, vehicle glass or architectural glass as well as metallic surfaces. KIWOMASK IJ 510 is applied to the surface to be coated using a digital printer. After the coating process, the resist can easily be removed in a manual or mechanical cleaning process with organic solvent cleaners such as KIWOCLEAN LM 606.

UV-curing sandblasting resist for metal, natural stone, ceramics and glass surfaces. Besides good sandblasting resistance, KIWOMASK UV 160 / 2 is also resistant to water and organic solvents. Can be easily removed as film. The transparent blue colouring (greenish / yellow after UV cross-linking) offers a good contrast to control print quality, however, at the same time enables the recognition of overprinted designs.

Screen-printable, UV-crosslinking, „liquid protective film“ for glass, metal, lacquered and printed surfaces, as well as various plastic substrates. It is ideal for partial or complete protection of scratch-sensitive plastic surfaces such as e.g., displays or control elements during further processing steps, such as subsequent printing, cutting or die-cutting.

KIWOMASK S 116 HV / S 117 LV are transparent, “liquid“ protective films for coating scratchand dirt-sensitive surfaces, e.g. to protect against spray mist in paint booths. Both are waterbased products and are supplied ready to use for different methods of application. KIWOMASK S 116 HV (HV = high viscosity) has a thicker consistency and is applied preferably with a paintbrush or roller on the surface to be coated. KIWOMASK S 117 LV (LV = low viscosity) is thinner and supplied ready to use for spray, dip or curtain coating.

Screen-printable, water-based protective film for scratch sensitive surfaces. After the application and subsequent drying, components are protected against mechanical attacks. It features excellent printability, flow and wetting properties, high mechanical strength and very good, residue-free peel-off properties. Due to its temperature resistance, it is also suitable for common thermoforming processes.

Easily removable “liquid” protective film for the all over protection of glass, plastic metal and other scratch-sensitive surfaces. KIWOMASK W 122 Colourless is colourless, water based and can be reduced with deionized or distilled water. After drying, the resist forms a flexible, water resistant and easily removable protective film.

“Liquid“ protective film which can either be applied over a large area or partially coated onto the surface to be protected. KIWOMASK W 128 is colourless, water-based and can be diluted with deionized or distilled water to adjust viscosity. After drying, it is water resistant and very resistant to mechanical stress. For instance, applied as a temporary protection onto scratch-sensitive surfaces (such as glass, metal and various plastics) prior to further processing steps.